Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

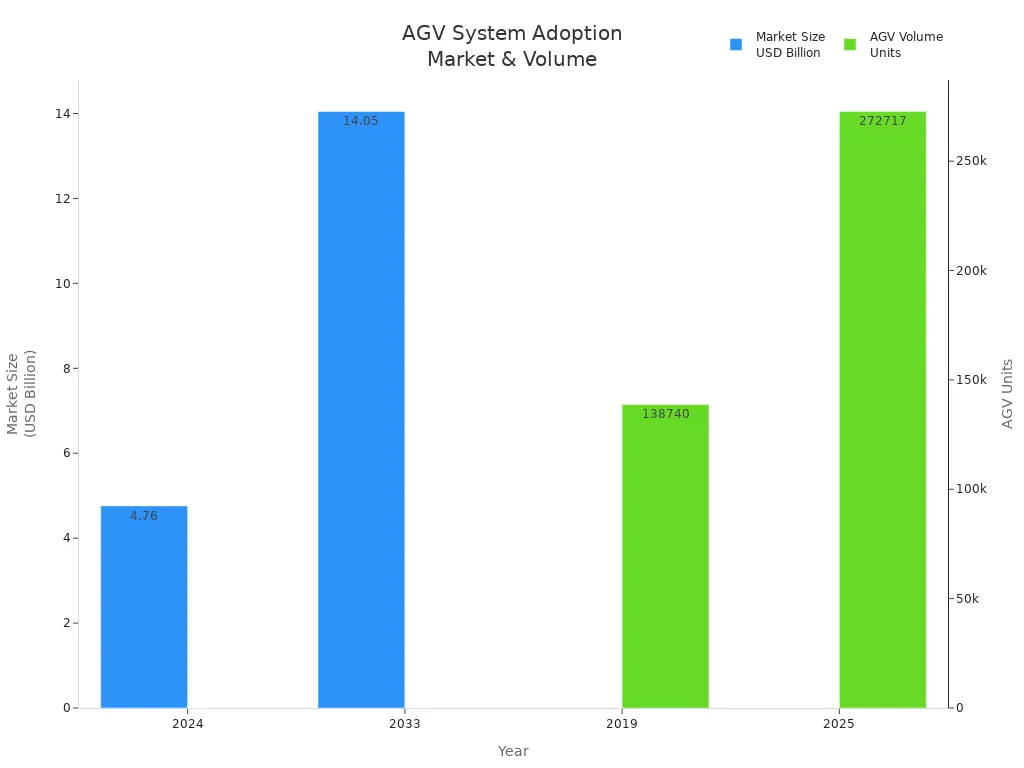

The adoption of an automated guided vehicle system continues to revolutionize how materials are managed in factories and warehouses. By integrating an automated guided vehicle system, you can boost productivity and lower labor costs, all while enhancing safety through advanced collision avoidance technology. An automated guided vehicle system enables precise material tracking and supports 24/7 operations, allowing you to meet increasing demands effortlessly. The market for automated guided vehicle system solutions is experiencing rapid growth, as illustrated below:

Metric | Value |

|---|---|

Market Size in 2024 | USD 4.76 Billion |

Market Forecast in 2033 | USD 14.05 Billion |

Market Growth Rate (2025-2033) | 12.15% |

Volume of AGVs in 2019 | 138,740 units |

Volume of AGVs in 2025 | 272,717 units |

CAGR (2020-2025) | 13.32% |

Indoor Segment Market Share (2023) | 80% |

With an automated guided vehicle system, you can minimize product damage and guarantee timely deliveries to storage or shipping docks. Think about the positive impact an automated guided vehicle system could have on your own operations.

Automated guided vehicle systems boost productivity by moving materials quickly and accurately, reducing transport time.

AGVs enhance workplace safety by handling repetitive tasks, minimizing human error, and including advanced collision avoidance technologies.

Integrating AGVs with warehouse management systems automates inventory updates, improving accuracy and efficiency.

Investing in AGVs can lead to significant long-term savings on labor costs, with many companies seeing a return on investment within 18-36 months.

AGVs offer flexibility to adapt to changing production needs, allowing businesses to scale operations easily.

You can see major improvements in efficiency when you use agvs in your facility. These vehicles move materials quickly and accurately, reducing the time it takes to transport goods. Many companies report impressive results after switching to agv solutions:

Denso achieved a 48% reduction in process defects.

33% of labor was reallocated to better positions, not eliminated.

Most agv systems deliver a return on investment within 18-24 months.

One agv can do the work of two or three full-time employees.

Damage costs drop by over 90% because of precise navigation.

Throughput increases, which can boost your revenue.

You can also compare the cost-saving mechanisms of agvs to traditional methods:

Mechanism | Description |

|---|---|

Increased Efficiency | Agvs operate faster than human workers, speeding up material handling. |

Reduced Labor Costs | Agvs remove the need for overtime, sick leave, and vacation pay. |

Minimized Damages | Collision avoidance features help prevent damage to products and equipment. |

Improved Safety | Agvs follow set paths and use sensors to avoid accidents. |

Agvs help you create a safer workplace. Fatigue and distraction often cause accidents, especially during long shifts. Studies show a 13% higher risk of accidents after a 10-hour shift and a 27.5% increase after 12 hours. Agv systems remove these risks by handling repetitive and tiring tasks. Automation reduces injuries linked to human error.

Agvs also help you meet strict safety standards. They include emergency stop buttons, warning lights, and alarms. Navigation and control systems prevent collisions. Operators receive training for safe startup, shutdown, and emergency response. These features make agvs a reliable choice for safety compliance.

Agvs automate many steps in your workflow. They move heavy loads, support high efficiency, and reduce the need for manual labor. You can use different types of agv, such as automated guided carts, tractor agvs, and forklift agvs, to match your needs. Agvs use guidance systems like magnetic tape, wires, or lasers to follow paths.

You can connect agvs to your warehouse management system or enterprise resource planning system. This integration lets agvs receive tasks, update inventory, and automate stocking based on real-time data. As a result, your operations become more accurate and productive. Agvs make it easier to scale up as your business grows.

An automated guided vehicle system gives you a powerful way to automate material handling in your facility. You use this technology to move goods, parts, or pallets without human drivers. The system relies on a fleet of automatic guided vehicle units that follow programmed routes and perform tasks with precision. You can trust an automated guided vehicle system to handle repetitive, heavy, or hazardous jobs, which helps you improve safety and efficiency.

You might wonder how an automated guided vehicle system compares to other solutions. Automated guided vehicles operate on fixed paths, using external guidance like magnetic strips or wires. This makes them ideal for structured environments such as warehouses and factories. In contrast, autonomous mobile robots (AMRs) use advanced sensors and artificial intelligence to navigate freely and adapt to changes in real time. AGVs stop when they encounter obstacles, while AMRs can reroute themselves automatically. The table below highlights the main differences:

Feature | Automated Guided Vehicles (AGVs) | Autonomous Mobile Robots (AMRs) |

|---|---|---|

Navigation Method | Fixed routes using external guidance (magnetic strips, wires) | Dynamic navigation using onboard sensors and AI |

Flexibility | Limited; must follow predefined paths | High; can adapt to changes in real-time |

Obstacle Handling | Stops and waits for obstacles to be cleared | Detects and navigates around obstacles autonomously |

Environmental Adaptability | Best in structured environments (warehouses, factories) | Operates efficiently in complex, unstructured environments |

Autonomy Level | Minimal onboard intelligence; follows simple programming | High autonomy; uses advanced mapping and navigation tech |

When you choose an automated guided vehicle system, you benefit from several core components and technologies that work together to deliver reliable performance. Here are the main features you should know:

Navigation systems: These guide each automatic guided vehicle along its path.

Communication and control systems: These allow you to monitor and direct your fleet in real time.

Sensors: These detect obstacles and help prevent collisions.

Fleet management: This software coordinates multiple vehicles for efficient operation.

Power and energy systems: These keep your agv system running, often with rechargeable batteries.

Software integration: This connects your agv system to warehouse management or enterprise resource planning systems.

You can use an industrial automated guided vehicle to move heavy loads, pallets, or parts between workstations. Many companies rely on a heavy load agv to transport bulky items safely and efficiently. The agv system supports 24/7 operation, which helps you meet production targets and reduce downtime.

Tip: Integrate your agv system with your inventory software to automate stock updates and improve order accuracy.

Navigation is the heart of any automated guided vehicle system. You have several options to choose from, each with its own strengths:

Laser Guidance: Uses laser beams and reflective targets for accurate positioning. You need to place reflectors carefully, but this method offers high accuracy.

Vision Guidance: Employs cameras to identify features in the environment. This method adapts well to changing layouts.

Natural Navigation: Relies on static features in your facility, such as walls or pillars, for positioning. This method is easy to install and reliable.

Magnetic Tape or Wire Guidance: Involves laying magnetic strips or wires on the floor. Your agv follows these paths precisely.

Inertial Navigation: Uses onboard sensors to track movement and position, which is useful for complex routes.

Optical Navigation: Utilizes cameras to follow lines or markers on the floor.

Each navigation method impacts your agv system’s performance. Laser and vision guidance provide high accuracy, while natural navigation offers easy installation. Magnetic tape and wire guidance work best in stable environments. You should select the method that matches your facility’s needs and the complexity of your material handling tasks.

The evolution of agvs has led to greater flexibility in routing and dispatching, especially in dynamic manufacturing settings. Modern agv navigation control systems manage route planning, obstacle detection, speed control, and error handling. This ensures safe and efficient operation, even as your facility grows or changes.

Safety is a top priority when you deploy an automated guided vehicle system. You want to protect your staff, equipment, and products. Today’s agv systems use advanced safety technologies to minimize risks:

Emergency stop buttons and warning lights alert workers to vehicle movement.

Sensors detect obstacles and stop the agv to prevent collisions.

Audible alarms warn people nearby when an agv is approaching.

Modern systems offer real-time monitoring and can integrate with centralized safety oversight platforms.

Compliance with industry safety standards ensures your agv system meets regulatory requirements.

Software updates allow you to improve safety features and maintain compliance as standards evolve.

You may face challenges such as regulatory compliance, cybersecurity threats, and interoperability with existing systems. Address these by choosing a reputable agv system provider and ensuring regular maintenance and updates.

Note: Always train your team on agv safety protocols and emergency procedures to maximize the benefits of your automated guided vehicle system.

By understanding the key features, navigation methods, and safety technologies, you can make informed decisions about deploying an automated guided vehicle system in your facility. This knowledge helps you optimize material handling, boost productivity, and create a safer workplace.

Automated guided vehicles come in several types, each designed for specific industrial applications. You can choose the right agv for your facility by understanding how each type works and where it fits best.

Tow vehicles are a popular choice for moving multiple carts or trailers at once. You see these agvs in metal fabrication, automotive plants, and warehouses. They help you streamline internal logistics and keep materials flowing. Electric tow tractors navigate narrow aisles and busy areas with ease. You save money because these agvs do not need fuel, and improved battery technology increases uptime. Zero emissions support your sustainability goals.

Tip: Tow vehicles offer agv advantages like efficiency, cost savings, and environmental benefits.

Main advantages of tow vehicles:

Navigate tight spaces and congested areas

Reduce operational costs with electric power

Support green initiatives with zero emissions

Unit load carriers handle pallets, containers, and other large items. You find these agvs in industries such as automotive assembly, aerospace, food processing, and hospitals. They move vehicles, aircraft parts, food products, medical supplies, and more. You can automate the transport of materials between workstations, storage, and shipping docks.

Industry | Types of Materials Handled |

|---|---|

Automotive Assembly | Vehicles and components |

Aerospace Manufacturing | Aircraft parts and components |

Food Processing | Food products and packaging |

Hospitals | Medical supplies and equipment |

Warehousing and Distribution | Various products and materials for storage |

Unit load carriers give you agv advantages like improved safety, reduced labor, and consistent delivery times.

Forklift agvs automate pallet stacking, stock retrieval, and production line support. You use these agvs in warehouses and manufacturing plants to boost productivity and safety. Forklift agvs operate without breaks, follow optimal paths, and maximize throughput. Advanced sensors and navigation systems help prevent accidents. Traditional forklifts cause many injuries each year, but agvs lower these risks.

Key agv advantages of forklift agvs:

Continuous operation for higher productivity

Fewer safety incidents due to autonomous navigation

Reliable handling of repetitive and heavy tasks

You can see the impact of agvs in many industries. Here are some examples of agvs in action:

Clairefontaine uses agvs for internal load transportation in its warehouse.

Kern Pharma employs agvs to move pallets from production lines to storage.

Novartis utilizes agvs for transporting goods between facilities.

Renault implements agvs to connect logistics and production centers.

Automated guided vehicles help you solve material handling challenges and improve your operations. You can select the right agv system based on your needs and industry requirements.

When you compare automated guided vehicle systems to manual material handling, you notice clear differences in both cost and efficiency. Automated guided vehicle systems require a higher initial investment, especially if you choose advanced models or custom features. Entry-level agv units can start at around $50,000, while more complex agvs may cost over $300,000. However, you save money over time because agvs reduce your ongoing labor costs. Manual systems have lower upfront costs, but you pay more for labor, training, and overtime.

System Type | Initial Investment Cost | Ongoing Labor Costs | Potential ROI |

|---|---|---|---|

Automated Guided Vehicle Systems | High | Low | High due to savings in labor |

Manual Material Handling Systems | Low | High | Lower due to ongoing labor expenses |

Automated guided vehicles work around the clock, which boosts your productivity and helps you meet tight deadlines. You also benefit from real-time data insights that optimize your workflow. Many companies see a return on investment in 18 to 36 months. If you want to know how do agvs work to improve efficiency, you will find that they automate repetitive tasks and deliver materials quickly and accurately.

Automated systems require a substantial initial investment, which can increase with customization.

Savings on manual labor and increased productivity can offset initial costs.

Manual systems have lower initial costs but incur higher ongoing labor expenses, including training costs.

You improve workplace safety when you use automated guided vehicle systems. Automated guided vehicles come with vision sensors, collision avoidance systems, and advanced navigation. These features help prevent accidents and protect your employees and equipment.

Safety Feature | Benefit |

|---|---|

Vision Sensors | Prevents collisions with obstacles |

Collision Avoidance Systems | Safeguards employees and equipment |

Navigation Systems | Ensures precise movement and route planning |

Safety Controls | Minimizes workplace accidents and injuries |

Automated guided vehicle systems automate hazardous and repetitive tasks, which reduces the risk of injuries. You also see fewer errors and less product damage because agvs move with precision. If you wonder how do agvs work to improve reliability, you will notice that they provide predictable, round-the-clock performance and use predictive maintenance to reduce downtime. Manual systems rely on human workers, which can lead to fatigue and mistakes, especially during long shifts.

AGVs can enhance efficiency by 50-70%, significantly improving workflows compared to manual labor.

AGVs utilize predictive maintenance through continuous performance monitoring, reducing unplanned downtime and maintenance costs.

AGVs are equipped with advanced obstacle detection and collision avoidance systems, which help reduce workplace accidents.

Automated guided vehicle systems give you more flexibility in your operations. You can scale your agv fleet as your business grows. AGVs adapt to changes in production layouts and can handle seasonal peaks in demand. Their modular design lets you add or remove units as needed. You can connect your agv system to warehouse management or ERP software for better decision-making.

AGVs automate repetitive transport tasks, enhancing operational flexibility.

They support just-in-time delivery, enabling quick responses to demand changes.

AGVs can handle seasonal peaks in warehousing, adapting to fluctuating workloads.

Their modular design allows for scaling as business needs evolve.

AGVs can navigate complex environments and adjust routes in real time.

Manual systems may struggle to keep up with rapid changes or increased workloads. Automated guided vehicles help you stay competitive by making your operations more responsive and efficient.

You gain many advantages when you choose an automated guided vehicle system for your facility. These systems boost productivity, improve safety, and increase accuracy in material handling. Leading automated guided vehicle manufacturers design solutions that fit your needs, offering modular designs and advanced software for real-time data. To get started, assess your current processes, talk with suppliers, and request demonstrations. Explore resources on best practices and involve your team early. By adopting an automated guided vehicle forklift or other AGV types, you strengthen your competitiveness and prepare for future growth.

An automated guided vehicle system uses driverless vehicles to move materials in your facility. You gain automated guided vehicle advantages like improved safety and efficiency. Leading automated guided vehicle manufacturers design these systems for warehouses, factories, and distribution centers.

An automated guided vehicle forklift lifts and transports pallets without a driver. You program routes, and the forklift follows them using sensors. Automated guided vehicle manufacturers build these forklifts to reduce accidents and boost productivity in your automated guided vehicle system.

You benefit from lower labor costs, fewer accidents, and higher accuracy. An automated guided vehicle system runs 24/7 and reduces product damage. Automated guided vehicle manufacturers offer solutions that help you scale operations and meet changing demands.

You can use an automated guided vehicle system in warehouses, factories, and hospitals. Automated guided vehicle forklifts move pallets, while other vehicles handle carts or containers. Automated guided vehicle manufacturers provide options for many industries.

You should compare automated guided vehicle manufacturers based on experience, support, and technology. Look for companies that offer automated guided vehicle forklifts and other vehicles. The right partner helps you maximize automated guided vehicle advantages in your system.