Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Automated guided vehicles (AGVs) bring immediate and lasting benefits to your warehouse and factory. You gain efficiency, safety, and cost savings by using AGV solutions for precise material handling. AGVs reduce labor costs, minimize product damage, and support industrial automation. You solve workflow bottlenecks by relying on AGV technology, which ensures timely deliveries and continuous material flow. With AGVs, you improve warehouse operations and adapt quickly to changing needs, making your business more competitive.

Benefits you can expect from automated guided vehicles and AGV solutions:

Increased efficiency and productivity

Enhanced safety in the warehouse

Sustained cost savings

Automated guided vehicles (AGVs) boost warehouse efficiency by moving materials quickly and precisely, reducing delays and bottlenecks.

AGVs improve safety by using sensors to avoid accidents and reduce human errors in material handling tasks.

Using AGVs lowers labor costs and product damage, leading to significant long-term cost savings.

Choosing the right AGV type and navigation technology helps your facility run smoothly and adapt to changing needs.

Careful planning, staff training, and system integration are key to successful AGV implementation and maximizing benefits.

You can transform your warehouse by using AGVs to automate material handling tasks. AGVs move pallets, bins, and raw materials across your facility with precision. You gain consistent delivery times and reduce bottlenecks in your material handling system. AGVs operate on programmed routes, which means you avoid delays and keep your production lines supplied.

AGVs support industrial automation by working alongside conveyors and robotic arms. You can scale your operations easily because AGVs adapt to changing layouts and production needs. Many applications of AGVs include moving goods between storage and shipping areas, replenishing inventory, and supporting just-in-time delivery.

Tip: AGVs help you optimize your warehouse layout by reducing the need for wide aisles and manual traffic, which increases storage capacity and efficiency.

AGVs reduce human error in warehouse operations. You eliminate mistakes caused by manual handling and driver fatigue. AGVs use sensors and safety features to prevent collisions and product damage. You can rely on AGVs to operate 24/7 without breaks, which boosts operational efficiency and lowers labor costs.

Here is a comparison between AGVs and traditional material handling equipment:

Feature | AGVs | Traditional Material Handling Equipment |

|---|---|---|

Operation | Fully autonomous, no human operator | Requires human operator |

Safety | Equipped with multiple sensors to prevent collisions and accidents | Dependent on operator skill and attention |

Accuracy | Consistent and precise performance | Varies with operator experience |

Operating Hours | Can operate 24/7 without breaks | Limited by human shifts and fatigue |

AGVs integrate with warehouse management systems, which improves traceability and control. You minimize dispatch and shipping errors and create a safer working environment. AGVs exceed international safety standards, reducing accidents and supporting efficient warehouse operations.

You increase flexibility in your warehouse by using automated guided vehicles. AGVs automate repetitive transport tasks and support just-in-time delivery, which helps you respond quickly to changes in demand. You can handle seasonal peaks in warehousing by deploying AGVs for picking, sorting, and replenishment.

AGVs connect with warehouse management and ERP systems, allowing you to make data-driven decisions and adapt your operations. Their modular design lets you scale your material handling system as your business grows. AGVs navigate complex environments and adjust routes in real time, which improves operational efficiency and resilience.

Note: AGVs give you greater agility and help you reallocate human resources to strategic activities, increasing overall benefits for your warehouse.

Automated guided vehicles (AGVs) are driverless machines that transport materials in factories and warehouses. You use an automated guided vehicle to move goods safely and efficiently. AGVs follow programmed routes and rely on advanced navigation systems to avoid obstacles and deliver items on time. You see automated guided vehicles in many industries, including automotive, logistics, and manufacturing.

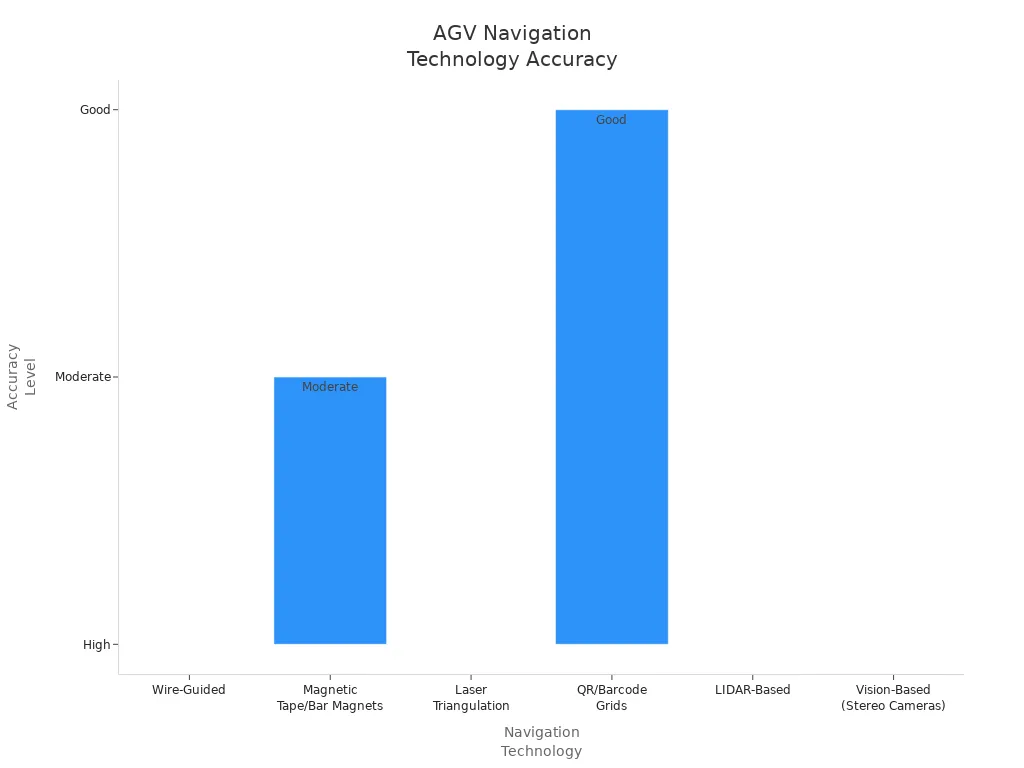

You choose from several navigation technologies when selecting an AGV for your facility. Each technology offers different levels of accuracy, flexibility, and cost. The table below shows how these navigation systems work and compares their strengths:

Navigation Technology | How It Works | Pros | Cons | Accuracy & Use Case Summary |

|---|---|---|---|---|

Wire-Guided | Follows embedded electromagnetic wire | High reliability, simple logic | Costly installation, inflexible | High accuracy on fixed routes; best for heavy-duty AGVs |

Magnetic Tape/Bar Magnets | Uses magnetic fields from floor tape | Easy to install and modify | Prone to wear and dirt interference | Moderate accuracy; suitable for mid-flexibility AGV routes |

Laser Triangulation | Uses reflective targets for location | High precision | Requires reflector maintenance | High precision in manufacturing AGV networks |

QR/Barcode Grids | Reads floor codes for localization | Cost-effective, scalable | Needs clean, consistent surfaces | Good accuracy in controlled indoor AMR environments |

LIDAR-Based | Builds 360° map with laser pulses | High-resolution, dynamic navigation | Higher cost, sensitive to reflectors | High accuracy in dynamic, obstacle-rich AMR environments |

Vision-Based (Stereo Cameras) | Uses 3D vision and AI for decisions | Infrastructure-free, intelligent | Computationally intensive, lighting-dependent | Adaptive, intelligent navigation with high accuracy in complex AMR tasks |

Tip: You improve workflow reliability by matching the right AGV navigation technology to your facility’s needs.

You find several types of AGVs designed for different tasks and environments. The most common types of agvs include:

Forklift AGVs: These autonomous forklifts move pallets and replace human drivers.

Unit Load Handlers: You use these AGVs to transport individual units like pallets or totes, streamlining receiving and shipping.

Heavy Burden Carriers: These AGVs handle very heavy loads such as steel plates and castings, often with self-loading features.

Towing AGVs: You deploy these driverless vehicles to tow multiple carts or trailers at once.

Automated Guided Carts (AGCs): These compact AGVs transport small quantities and feed assembly lines.

Custom AGVs: You can order AGVs tailored to your specific needs, including payload, size, and navigation technology.

Automated guided vehicles support many industries. For example, General Motors uses custom AGVs to deliver materials in automotive manufacturing. Global Logistics & Fulfillment relies on autonomous stockchasers to move pallets in warehouses, boosting productivity. DHL integrates AGVs for trailer loading, streamlining logistics. Boeing uses automated guided carts in aircraft assembly to improve precision and speed. These applications of agvs show how automated guided vehicles help you improve workflow, reduce manual labor, and enable smart factory operations.

Note: You increase efficiency and safety by choosing the right types of agvs for your facility’s needs.

Automated guided vehicles bring powerful advantages to your warehouse and manufacturing operations. When you deploy agvs, you unlock new levels of efficiency, safety, and cost-effectiveness. The key benefits of automated guided vehicles include measurable gains in productivity, improved workplace safety, and significant cost savings. Let’s explore how agv technology transforms your workflow and delivers these benefits.

You boost efficiency and productivity when you use agvs in your warehouse or factory. AGVs automate material handling, which means you move goods faster and more accurately. You eliminate delays caused by manual transport and reduce the risk of bottlenecks. AGVs work around the clock, so your warehouse operations never slow down due to breaks or shift changes.

Many companies have reported dramatic improvements after adopting agv solutions. The table below shows how leading organizations increased efficiency and productivity with automated guided vehicles:

Company | Reported Measurable Increase in Efficiency/Productivity |

|---|---|

Toyota | Significant improvement in material distribution efficiency through AGV integration with lean production. |

Amazon | Order processing speed increased by over 40% after deploying warehouse AGVs. |

JD Logistics | Efficiency increased by 3-5 times; picker steps reduced by more than 70%. |

SF Express | Significant improvement in express shipment processing efficiency via AGVs. |

You can see that agvs deliver real results. In warehousing, agvs streamline picking, sorting, and replenishment tasks. You reduce the number of steps workers take and speed up order fulfillment. AGVs also support just-in-time delivery, which keeps your production lines running smoothly. These benefits of agvs help you stay competitive and meet customer demands with greater operational efficiency.

Tip: You can scale your agv fleet as your business grows, ensuring that your warehouse adapts quickly to changes in demand.

Safety features are a core advantage of agvs. When you introduce automated guided vehicles, you reduce workplace accidents by removing workers from hazardous material handling tasks. AGVs follow controlled pathways and use advanced safety features like sensors, collision avoidance systems, and intelligent traffic management. These technologies prevent accidents and create a safer, more predictable environment.

AGVs also help you comply with occupational safety standards. Here are some ways agvs improve safety and compliance:

AGVs use sensor-based navigation and collision warning systems to reduce human error and prevent accidents.

They follow defined guidepaths with clearly marked hazard and restricted zones to minimize collision risks.

AGVs stop automatically when obstacles are detected, enhancing operational safety.

Compliance with ANSI/ITSDF B56.5 standard ensures safety requirements specific to AGVs are met.

OSHA’s General Duty Clause requires a hazard-free workplace, which AGVs help achieve by reducing recognized hazards.

Comprehensive training ensures operators and staff understand hazard zones and interact safely with agvs.

Safety measures include marked aisles, audible and visual alarms at blind corners, mirrors, and strict maintenance protocols.

AGVs avoid unsafe conditions by following manufacturer guidelines and prohibiting unauthorized modifications.

You create clear boundaries between human and robotic work zones, which lowers the risk of accidental entry into dangerous areas. By reducing physical demands on workers, you decrease fatigue-related errors and help your team make safer decisions. These safety features make agvs a smart investment for any warehouse or manufacturing facility.

Note: AGVs exceed international safety standards and help you maintain a safer workplace for everyone.

Cost-effectiveness is one of the most important benefits of agvs. When you switch from manual vehicles to agv systems, you cut operating costs, reduce labor expenses, and lower product damage rates. The table below compares annual costs before and after agv integration:

Cost Category | Manual Vehicles (Annual) | Automated Guided Vehicles (Annual) |

|---|---|---|

Operating cost (excluding capital) | $196,500 | $36,000 |

Driver salaries | $160,000 | $0 |

Driver overheads | $24,000 | $0 |

Goods damage cost | $10,000 | Reduced (implied) |

You can save over $160,000 per year by eliminating driver wages and reducing damage costs. Many companies reach a break-even point in just over two years, even with the initial investment in agv technology. AGVs also lower maintenance costs and minimize time lost searching for products.

Here’s how agvs improve cost-effectiveness and return on investment:

AGVs replace manual material handling, which significantly reduces labor costs.

You see fewer damaged goods, which saves money on replacements and repairs.

AGVs decrease downtime and keep your warehouse running at peak efficiency.

Strategic deployment of multiple agvs across your enterprise maximizes financial returns.

By investing in automated guided vehicles, you gain long-term cost savings and improve your bottom line. AGVs help you achieve a more efficient, safer, and cost-effective operation.

Callout: AGVs deliver measurable financial benefits and support sustainable growth in warehousing and manufacturing.

Implementing agvs in your factory or warehouse requires a structured approach. You need to assess your current workflow, prepare your facility, select the right agv solutions, and ensure smooth integration with existing systems. By following these steps, you maximize cost-effectiveness and achieve reliable results.

Start by evaluating your current material handling and workflow. You identify bottlenecks, repetitive tasks, and areas where manual labor slows down operations. Map out the movement of goods, from receiving to shipping, and note where delays or errors occur.

You should involve key stakeholders, including warehouse managers, IT staff, and production planners, to gather insights. This assessment helps you set clear goals for agv deployment and choose solutions that address your most pressing challenges.

Tip: Use process mapping tools to visualize your workflow and highlight areas where agvs can deliver the greatest impact.

Prepare your facility for agv vehicle deployment by making necessary infrastructure modifications. Most agvs require predefined guidance systems to follow fixed paths. You may need to install magnetic tapes, wires, or sensors in the floor to enable accurate navigation.

Consider these common infrastructure changes before introducing agvs:

Install physical navigation aids such as magnetic tape or embedded wires for route guidance.

Add wireless emitters or sensors to support collision avoidance and communication.

Update routes by modifying navigation markers or digital maps, which reduces the need for major structural changes.

Review your facility layout to ensure agvs can move efficiently between workstations and storage areas.

Some agv solutions offer flexible navigation, allowing you to adjust routes with software updates and minor changes. This flexibility supports cost-effectiveness and minimizes disruption to your warehouse operations.

Selecting the best agv for your application involves several criteria. You need to consider the type and weight of loads, the operating environment, and the level of accuracy required for load placement.

When choosing agvs, focus on these factors:

Match the agv type (unit load, forklift, tugger) to your specific material handling needs.

Choose navigation technology based on your warehouse environment—laser guidance for precision, wire guidance for fixed paths, or visual guiding for cost-effectiveness.

Ensure the agv’s accuracy meets your load placement requirements to prevent damage.

Verify compatibility with your warehouse management and logistics systems.

Decide between standard agvs for easier maintenance or bespoke agvs for heavy or specialized loads.

Equip agvs with safety features like detection sensors and warning signals.

Consider the flexibility needed for navigation and task execution to match your operations.

Note: The right agv solutions improve efficiency, safety, and cost-effectiveness in your warehouse.

Successful agv implementation depends on seamless integration with your current systems. Modern agvs synchronize with ERP, warehouse management, and production planning systems to support just-in-time delivery and flexible manufacturing.

Best practices for integration include:

Connect agvs to ERP, MES, and warehouse management systems for real-time inventory and order management.

Use handheld devices linked to your systems to scan orders and coordinate material delivery.

Analyze workflows to plan integration and redundancy, starting with pilot areas.

Address challenges such as data format compatibility, real-time communication, system reliability, and security protocols.

Integrate agvs with barcode systems for efficient inventory tracking.

Integration typically takes several months, depending on facility size and complexity. You improve throughput and flexibility by ensuring agvs work smoothly with your existing solutions.

Before full deployment, run a pilot program to test agv solutions in a controlled area. Monitor key performance indicators to measure success and identify areas for improvement.

Track these KPIs during the pilot phase:

Order accuracy to evaluate correct order fulfillment.

Inventory turnover to assess efficient inventory management.

Labor efficiency to measure productivity improvements.

You use these metrics to spot bottlenecks, integration issues, and process gaps. Continuous monitoring during the pilot phase helps you optimize agv performance and prepare for scaling up.

Callout: A successful pilot program builds confidence and ensures your agv solutions deliver measurable results.

After a successful pilot, scale up agv deployment across your facility. Comprehensive training prepares your staff to work safely and efficiently alongside agvs.

Effective training programs cover these components:

Training Program Components | Description |

|---|---|

Fundamentals of AGV Technology | Covers agv types, benefits, system components, and navigation technologies. |

System Design and Planning | Focuses on designing agv routes, integration with warehouse systems, and operational planning. |

Installation and Configuration | Best practices for setting up agv infrastructure and software configuration. |

Operation and Management | Training on safe operation, fleet management, and performance monitoring of agvs. |

Maintenance and Troubleshooting | Routine maintenance, common issues, and troubleshooting techniques to ensure reliability. |

Safety and Compliance | Emphasizes safety protocols and regulatory compliance when working alongside agvs. |

Complementary Software Skills | Includes Artificial Intelligence, Data Analytics, Business Automation, and IT Automation training |

You ensure staff understand agv operation, safety protocols, and system integration. Ongoing training supports continuous improvement and maximizes the benefits of your agv solutions.

Tip: Regular refresher courses and hands-on practice help your team adapt to new agv technologies and maintain high performance.

Introducing agvs into your facility brings many benefits, but you will face some challenges of implementing agvs. Understanding these challenges and applying the right solutions helps you achieve a smooth transition and maximize your investment.

You may encounter technical challenges when connecting agv systems to your existing software and hardware. Integration with warehouse management or ERP systems can be complex. Data formats, real-time communication, and system reliability often require careful planning. To overcome these issues, work closely with your agv vendor. Many vendors offer integration solutions that ensure your agv vehicle communicates effectively with your current systems. Continuous monitoring and regular updates help you maintain system performance and address any technical problems quickly.

Tip: Schedule regular check-ins with your vendor to review integration progress and resolve issues early.

Legacy facilities often need upgrades before you can deploy agvs. Many older plants have concrete floors with worn joints from years of forklift use. These uneven surfaces can disrupt the precise movement of an agv. You should fill and grind floor joints to create a smooth surface. This step is critical for reliable agv operation. Other facility modifications may include installing navigation markers or updating lighting for safety features. Planning these changes in advance ensures your agvs perform at their best.

Adopting agvs affects your workforce. Change management strategies help your team adapt to new technology. Involve employees early in the project and communicate openly about upcoming changes. Provide training and support to build confidence and skills. The table below highlights key strategies for successful change management:

Strategy Aspect | Benefit for Workforce Adaptation |

|---|---|

Early Employee Involvement | Reduces uncertainty and builds acceptance |

Transparent Communication | Builds trust and addresses concerns |

Clear Responsibility Structures | Provides clarity and reduces anxiety |

Employee Support and Training | Enhances skills and confidence |

Focus on Safety and Process | Ensures physical safety and proper automation scope |

You can reduce resistance by listening to employee concerns and offering ongoing support. These solutions help your team embrace agvs and use safety features effectively.

Note: Collaboration with vendors and continuous monitoring are essential solutions for overcoming the challenges of implementing agvs.

You need to measure the success of your agv deployment to ensure you reach your goals. Key performance indicators (KPIs) help you track progress and identify areas for improvement. You can use these KPIs to evaluate how well your agvs perform in your warehouse or factory.

Some important KPIs for agv systems include:

Throughput Rate: Measures how many loads your agvs move per hour or shift. Higher throughput means better efficiency.

Order Accuracy: Tracks the percentage of orders delivered without errors. High accuracy shows your agv system works reliably.

Downtime: Monitors the time your agvs spend out of service. Less downtime means higher productivity.

Labor Savings: Compares labor costs before and after agv integration. Lower labor costs show the value of automation.

Energy Consumption: Measures how much energy your agvs use. Efficient agv vehicles help reduce operating costs.

You can use a table to organize and review your KPIs:

KPI | What It Measures | Why It Matters |

|---|---|---|

Throughput Rate | Loads moved per hour/shift | Shows efficiency |

Order Accuracy | Correct deliveries (%) | Ensures reliability |

Downtime | Time agvs are not working | Impacts productivity |

Labor Savings | Labor cost reduction | Proves cost-effectiveness |

Energy Consumption | Power used by agv fleet | Affects operating expenses |

Tip: Review your KPIs regularly to spot trends and make data-driven decisions for your agv system.

You can boost agv performance by using continuous improvement strategies. Modern approaches use advanced algorithms and digital tools to help your agvs adapt and improve over time. For example, you can use multi-agent reinforcement learning based on graph neural networks. This method lets your agvs learn from real-time data and make better decisions in complex environments. Centralized training with distributed execution helps your agv fleet plan paths more efficiently and handle unexpected changes.

Another way to improve agv efficiency is by combining hybrid genetic algorithms with digital twin technology. The digital twin creates a virtual model of your warehouse and synchronizes it with real-time agv data. This setup helps you test new strategies and optimize routes without disrupting daily operations. The hybrid genetic algorithm prevents your agvs from getting stuck in inefficient patterns and finds the shortest paths for each task. You can see results like shorter travel distances and lower empty vehicle rates, which lead to higher efficiency and better use of your agv vehicles.

You should keep your agv integration flexible and open to updates. Regularly analyze performance data and adjust your system as needed. Encourage your team to suggest improvements and stay informed about new technologies. Continuous improvement ensures your agvs deliver long-term value and keep your operations competitive.

Note: Ongoing optimization and adaptation help your agv system handle new challenges and maintain top performance.

You can transform your factory workflow with agv solutions. Many companies report long-term improvements such as:

Enhanced efficiency and productivity from automated material transport

Improved safety by reducing workplace accidents

Cost-effectiveness with lower labor costs and 24/7 operation

Flexibility and scalability for changing needs

Environmental benefits from battery-powered agv vehicles

Future upgrades with AI and IIoT integration

Most companies consult agv providers to select the right system, customize features, and ensure safe, efficient integration. You may see a longer return on investment due to installation needs, but the benefits of agv technology make the effort worthwhile. Assess your operations and reach out to experts for tailored advice.

Automated Guided Vehicles use sensors, software, and navigation systems to move materials in your factory. You program routes for each AGV vehicle. These autonomous vehicles follow paths, avoid obstacles, and deliver goods safely.

Yes, you can use Automated Guided Vehicles as an autonomous forklift. These AGV vehicles lift, move, and stack pallets without a driver. You improve safety and reduce labor costs by switching to an autonomous forklift.

Automated Guided Vehicles use sensors and smart controls to avoid collisions. You keep workers safe by removing them from dangerous tasks. AGV vehicles follow set paths and stop when they detect obstacles.

You need to check sensors, batteries, and wheels on each AGV vehicle. Regular software updates keep your autonomous vehicles running smoothly. You should follow the manufacturer’s maintenance schedule for best results.

Yes, you can use Automated Guided Vehicles in small warehouses. AGV vehicles fit many layouts and handle different tasks. You boost efficiency and safety, even in tight spaces, with these autonomous vehicles.