Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

Warehouse racking systems are the backbone of material storage and organization in many industrial environments. From small warehouses to large-scale distribution centers, the role of these racking systems cannot be overstated. However, ensuring the safety of warehouse racking systems is critical to preventing accidents, protecting inventory, and ensuring smooth warehouse operations. This article explores the safety considerations, common hazards, best practices, compliance with regulations, and expert opinions regarding warehouse racking safety.

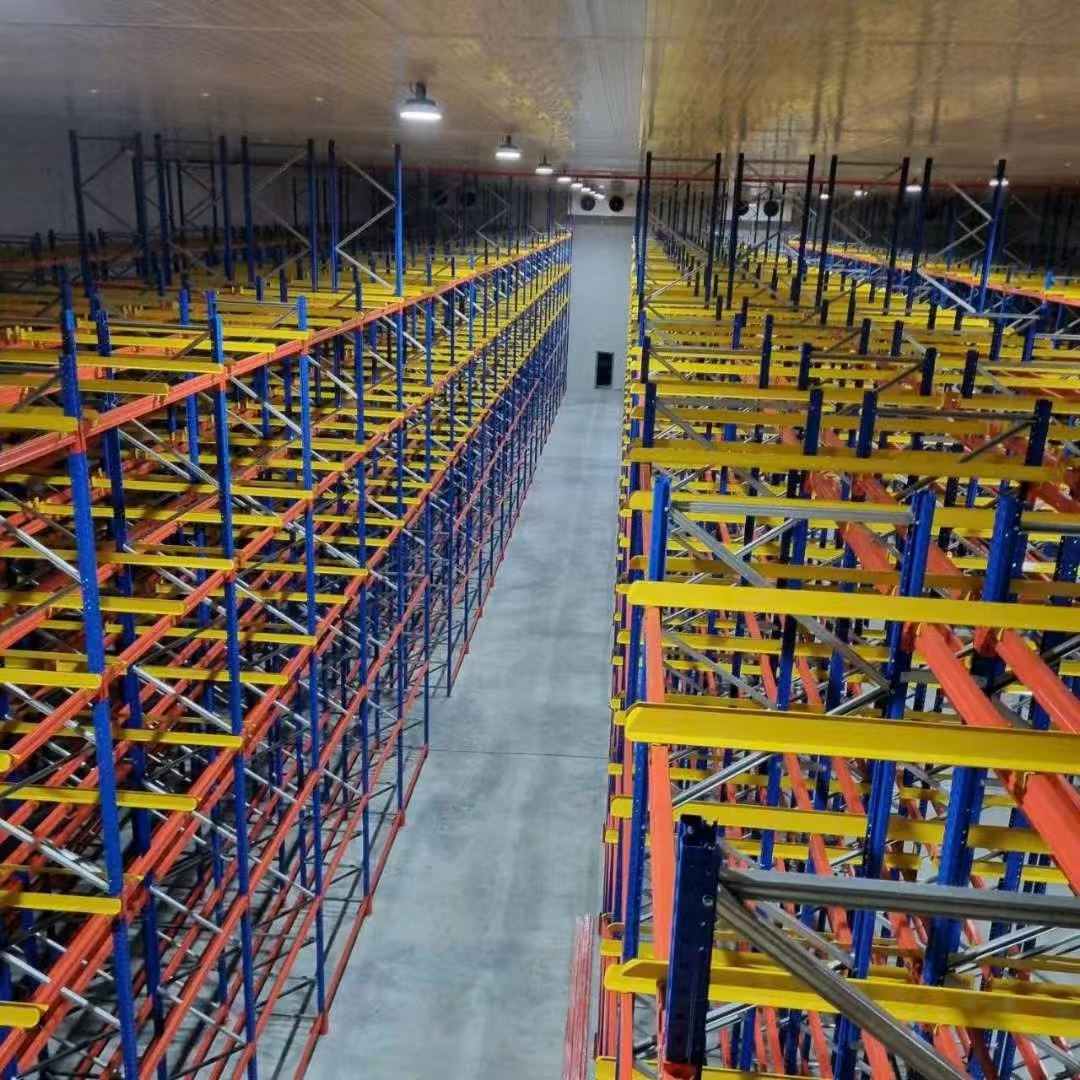

Warehouse racking systems are designed to maximize storage space while maintaining easy access to stored items. There are several types of racking systems used in warehouses, each suited to specific storage needs. Some of the most common types include:

Pallet Racking: A system that uses horizontal rows of steel beams to store materials on pallets.

Shelving Systems: Ideal for smaller items, these systems provide vertical storage in adjustable shelves.

Mezzanine Racking: Adds additional storage space by utilizing the overhead area of a warehouse, ideal for non-perishable goods.

These systems enable businesses to store large quantities of goods in a limited space, optimizing the storage capacity of the warehouse. However, ensuring their safety requires proper installation, design, and ongoing maintenance.

The strength and stability of a warehouse rack system depend on its structural design and the materials used. The racks must be able to support the weight of stored goods without the risk of collapsing. Regular structural integrity checks are essential to ensure that the racks can withstand heavy loads and prevent accidents.

A well-designed rack system helps reduce risks such as tipping, overloading, and poor weight distribution. For example, adjustable racks need to be properly balanced, and safety measures should be incorporated to prevent overloading. Proper design can also help improve warehouse flow and reduce the chances of accidents.

Material handling involves the safe loading and unloading of goods onto racking systems. Forklifts and pallet jacks are often used to move materials in and out of racks. However, if not used correctly, these tools can cause rack damage, leading to a potential collapse. Warehouse personnel should be trained in safe loading and unloading practices to minimize risks.

One of the most common safety hazards in warehouse racking systems is overloading. Placing too much weight on a single rack or pallet can lead to rack collapse or material damage. It is essential to adhere to the load-bearing capacity specified by the manufacturer and to conduct regular weight checks to ensure safe storage.

Racking systems must be installed according to the manufacturer’s specifications. Improper installation, such as failure to secure beams properly or misalignment of racks, can lead to instability. Always ensure that the installation process is carried out by trained professionals who understand the importance of correct assembly.

Over time, racks can become damaged due to regular use or collisions with material handling equipment. Even minor damage, such as bent beams or cracked components, can compromise the stability of the entire racking system. Regular inspections are vital for detecting damaged racks before they pose a safety risk.

Forklift collisions are a significant threat to warehouse racking systems. Impact from a forklift can damage beams, crossbars, or supports, weakening the structure of the rack. Installing protective barriers and ensuring safe forklift operation can help reduce these incidents.

Regular inspections are essential for maintaining the safety of warehouse racks. Inspections should include checking for any damage, wear, or misalignment. Any issues discovered during inspections should be addressed immediately to prevent accidents.

Warehouse workers and forklift operators should receive regular safety training on how to handle racking systems and materials. They should be taught how to load, unload, and store goods safely to avoid overloading racks and damaging the system. Training also includes understanding the load limits and how to safely maneuver equipment around racks.

In high-traffic areas or where racks are under significant strain, additional reinforcement may be necessary. This can include adding guardrails to protect racks from forklift impacts or installing extra supports to increase load-bearing capacity. Reinforcement can significantly enhance rack safety and prolong the lifespan of the system.

Warehouse racking systems are subject to several safety standards and regulations, including those set by the Occupational Safety and Health Administration (OSHA). OSHA provides guidelines for warehouse safety that cover everything from load capacity to the proper design and installation of racking systems.

Adhering to these standards helps ensure that warehouses operate safely, minimizing the risk of injury or property damage. Failure to comply with OSHA regulations can result in fines and increased liability in the event of an accident.

In addition to OSHA, organizations like the Rack Manufacturers Institute (RMI) and the American National Standards Institute (ANSI) also provide guidelines for warehouse racking systems. These standards cover aspects such as design, installation, and maintenance, ensuring that warehouses adhere to best practices in safety.

Advancements in warehouse technology have led to the development of automated systems that can monitor the condition of racking systems in real-time. These systems can detect issues such as overloading or rack misalignment and alert warehouse managers immediately. This proactive approach helps prevent accidents before they occur.

Smart racking systems incorporate sensors and tracking technology to monitor the status of stored materials. These systems can automatically adjust to optimize space and load distribution, reducing the risk of overloading and rack failure.

Innovations in materials, such as reinforced steel or impact-resistant coatings, have made modern racking systems more durable and capable of withstanding warehouse stresses. These design improvements help enhance both the safety and longevity of racking systems.

Axiom Operations emphasizes the importance of having a comprehensive safety guide that outlines the best practices for managing warehouse racking systems. They stress the need for businesses to regularly assess their racking systems and ensure proper maintenance to reduce the likelihood of accidents.

QMH Inc. highlights the critical role OSHA plays in ensuring warehouse racking safety. They note that complying with OSHA regulations helps reduce workplace accidents and create a safer environment for workers. Their expertise stresses the importance of adhering to safety standards in racking system installation.

Racking World advises warehouses to be mindful of the risks of improper installation and to always follow safety standards when setting up racking systems. They also recommend frequent inspections and employee training as essential components of any safety program.

RMI Rack Safety offers insight into the elements of an effective rack safety program. They recommend a focus on preventive maintenance, employee education, and regular safety audits to ensure racking systems remain safe and operational.

SSI Schaefer advocates for the use of automation and smart racking systems to improve safety. Their approach focuses on leveraging technology to provide real-time data on the condition of warehouse racking systems, allowing for quick action when issues arise.

4Dock highlights the importance of adhering to OSHA’s compliance guidelines for warehouse racking systems. They provide a clear framework for warehouse managers to follow to ensure that their racking systems meet safety standards and reduce the risk of accidents.

The safety of warehouse racking systems is paramount in preventing accidents and ensuring the smooth operation of a warehouse. By following best practices, complying with safety standards, and incorporating new technologies, warehouse managers can significantly reduce risks and improve the safety of their racking systems. Regular inspections, employee training, and proper design are key factors in maintaining a safe environment for all personnel.