Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

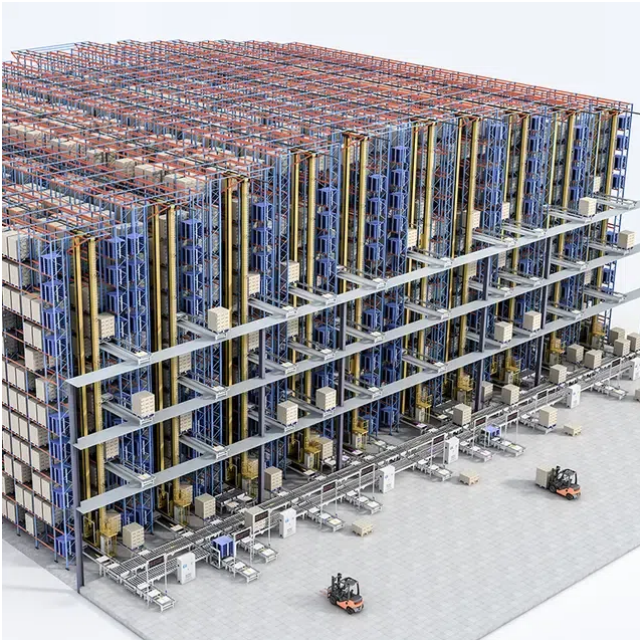

Warehouse racks play a crucial role in storage and logistics, ensuring that goods are stored efficiently and safely. However, without regular inspection, racks can become dangerous, leading to safety issues, operational disruptions, and damage to inventory. This article provides a step-by-step guide on how to inspect a warehouse rack, why inspections are necessary, and best practices to follow. We’ll also explore different industry viewpoints on warehouse rack inspections.

The primary reason for inspecting warehouse racks is safety. A damaged rack can collapse under the weight of goods, leading to injuries or fatalities. Regular inspections help detect issues like bent beams, unstable uprights, and faulty anchors before they pose a serious risk to workers.

Regular rack inspections ensure that the warehouse operates smoothly and productively. A well-maintained rack system maximizes storage space, optimizes workflow, and minimizes downtime for repairs. This leads to improved operational efficiency and reduced costs associated with maintenance.

Warehouse racks must meet safety regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and the RMI (Rack Manufacturers Institute). These regulations ensure that racks are structurally sound and that proper inspections are conducted to avoid penalties.

Warehouse racks are a significant investment. Regular inspections help identify minor issues that can be fixed before they lead to costly replacements. By catching problems early, warehouse managers can extend the lifespan of their rack systems, maximizing their return on investment.

Uprights (also known as columns) and beams are the core components of a warehouse rack system. During inspections, check for any bent, cracked, or rusted uprights, as well as any deflection in beams that could indicate overloading.

Braces and connectors are the links that hold the beams and uprights together. Inspect them for any loose fasteners, rust, or signs of fatigue. A failure in braces or connectors can lead to instability in the rack structure.

The footplates of a warehouse rack are crucial for ensuring stability. Check the footplates for any signs of damage or corrosion and ensure that they are securely anchored to the floor. Loose or damaged anchors can cause the rack to tip over, leading to safety hazards.

Each warehouse rack should have clear load capacity labels that indicate the maximum weight the system can safely hold. Ensure these labels are visible, intact, and accurate. Misuse of the rack system due to unclear or incorrect labeling can lead to dangerous overloads.

Inspect the aisles around the rack system to ensure they are clear of obstructions. Proper clearance is essential for safe forklift operation and smooth material handling. Aisles that are too narrow or cluttered can cause accidents and reduce operational efficiency.

Before starting the inspection, gather the necessary tools, including a flashlight, tape measure, level, plumb-bob, camera, and personal protective equipment (PPE). Ensuring proper safety gear is worn is crucial for protecting yourself during the inspection.

Begin by walking through the warehouse, inspecting each rack from floor level upward. Look for any obvious signs of damage such as rust, bent or misaligned components, and missing parts. This visual inspection should cover the entire rack system, including the uprights, beams, braces, and footplates.

Check the load distribution on each rack. Ensure that goods are placed evenly across the beams and not exceeding the rack’s load capacity. Overloaded racks can lead to beam deflection, which could compromise the integrity of the entire system.

Pay special attention to any damage caused by forklifts or other equipment. Look for bent beams, cracked uprights, or any twisted components. Misalignment can also occur over time, so it's important to check that all parts are properly aligned.

Ensure that the rack system is properly anchored to the floor and that footplates are secure. Use a level to check for any tilting or unevenness in the rack system. Any signs of floor settlement should be addressed immediately, as it could lead to structural instability.

Examine the aisles between racks to ensure they are wide enough for forklift operation and free of obstacles. The warehouse environment should also be inspected for factors like temperature and humidity, which can cause corrosion over time.

As you inspect the racks, document any issues you find. Take photos of any damage and create a detailed report that includes the location, severity, and suggested repairs. Proper documentation ensures that repairs are addressed promptly and helps maintain a history of inspections for compliance purposes.

Once the inspection is complete, decide on the necessary actions: repair, replace, or restrict use of damaged racks. Schedule repairs or maintenance and ensure that any safety concerns are addressed immediately.

The frequency of inspections depends on the size of the warehouse and the amount of traffic. A general guideline is to perform visual inspections monthly, with more detailed inspections (e.g., structural and load tests) occurring annually. In high-traffic areas, inspections may need to be more frequent.

It is recommended that warehouse staff receive training in rack inspection and can conduct regular visual checks. However, more complex inspections, especially those involving structural integrity, should be performed by qualified professionals or engineers.

Forklift Impact Damage: Collisions with racks by forklifts can cause bent uprights, damaged beams, or dislodged components.

Beam Deflection: Overloading racks beyond their rated capacity can lead to beam deflection, which compromises the strength of the system.

Rust and Corrosion: Exposure to humidity or harsh environments can cause racks to corrode, leading to weakened structures.

Overloading and Uneven Load Distribution: Improperly stacked goods or overloading can lead to rack instability and increased risk of failure.

Maintain a Regular Inspection Schedule: Consistency is key to ensuring the longevity and safety of warehouse racks. Follow a regular schedule for inspections and adhere to recommended intervals for more thorough checks.

Use Protective Devices: Install column guards, end-of-aisle barriers, and proper signage to prevent accidental damage to racks.

Train Warehouse Staff: Educate workers on how to spot early signs of rack damage, such as bent uprights or overloaded racks.

Keep Records: Document all inspections and repairs for compliance and future reference. This can help identify recurring issues and improve the overall maintenance strategy.

In conclusion, inspecting warehouse racks is crucial for ensuring the safety and efficiency of the warehouse environment. By following a systematic inspection process, maintaining regular checks, and taking corrective actions when needed, warehouse managers can prevent costly accidents and maintain smooth operations. Always ensure that inspections are documented, and involve qualified personnel when necessary to ensure comprehensive rack safety and compliance.