Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

Installing warehouse racking is a vital process that ensures effective storage and efficient workflow in your warehouse. A well‑designed racking system not only maximizes space but also improves inventory management, reducing operational costs and improving safety. In this article, we will walk you through the essential steps of installing a warehouse rack system, including warehouse rack and shelf options, site preparation, and safety guidelines to ensure a smooth installation process.

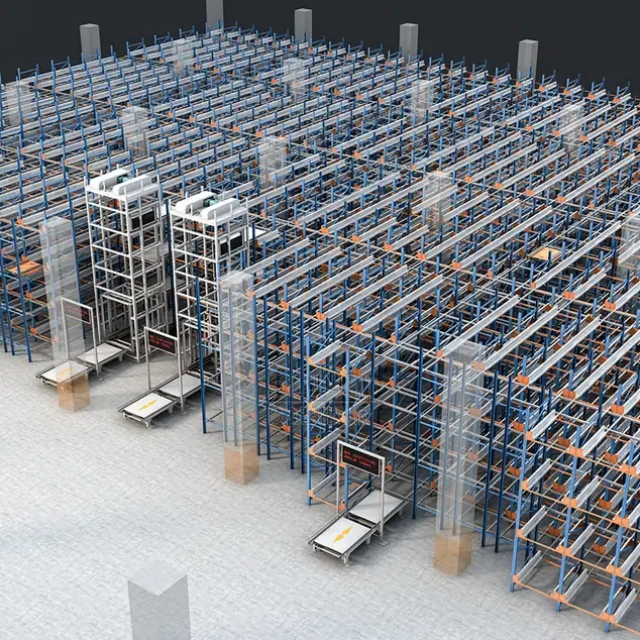

A warehouse rack is a storage system designed to support and organize heavy-duty loads within a warehouse. It is a robust structure used to store items in a manner that maximizes available space, allowing for easy access and efficient inventory management. These racks are typically designed with adjustable beams and columns, providing flexibility for various storage needs.

Warehouse racks and shelves refer to the different types of systems used to store items of varying sizes and weights, from heavy pallets to smaller, lighter items stored on shelves. Pallet racking, selective racking, and shelving are all common configurations used in warehouses based on the type of goods being stored.

Before you begin the installation of your warehouse rack, a well-thought-out plan is crucial. The following steps should be followed during the planning stage:

The first step in planning for a warehouse racking system installation is assessing the physical condition of your warehouse. This includes checking the floor strength, slab condition, and space layout. It’s important to ensure that the floor is level, free of obstructions, and capable of supporting the weight of the racking system. Warehouse racking systems can be quite heavy, so assessing the slab’s PSI (pounds per square inch) strength is critical.

To select the right type of racking, it’s essential to determine the weight and dimensions of the products that will be stored. Pallet racks, for example, are designed to carry heavy items, while light-duty shelving systems may suffice for smaller products. Understanding the load capacity of your warehouse rack is vital to avoid overloading the system, which can lead to safety issues.

Proper warehouse layout design plays a significant role in optimizing space and workflow. The racking system should be arranged to allow easy movement for workers and equipment. Aisle widths should be planned according to the size of the forklifts or Automated Guided Vehicles (AGVs) being used, and there should be enough space to navigate between racks without risking damage to the inventory or the racking system itself.

Ensure that your installation complies with local safety standards, building codes, and regulations. Certain warehouse racking systems may require permits, particularly if they are tall or used in seismic zones. It is always advisable to check with local authorities before proceeding with installation to ensure full compliance.

Selecting the correct warehouse rack system depends on your storage needs. Are you storing heavy pallets, or do you need smaller, more flexible shelving for individual products? Consider the structure’s dimensions, the load it will support, and how easy it is to install and maintain.

Gather the necessary tools, including drills, levels, and anchors, and make sure you have a qualified installation team. Training workers to safely handle the racking system installation ensures safety during the process.

Before installing a warehouse rack, it’s essential to properly prepare the site and floor. This ensures a solid foundation for your racking system, which is vital for safety and performance. Follow these steps:

Clear the installation area of any obstructions, debris, or existing shelving. Mark the layout lines on the floor to define the exact placement of the warehouse rack system.

Verify that the concrete floor is strong enough to support the racking system. Check the thickness and condition of the slab. It is critical that the concrete is in good condition, free of cracks or irregularities. The floor should also be level to ensure the racks are properly aligned.

Once the layout is defined, mark the footplate positions for the vertical columns. Accurate placement of the footplates ensures that the racking system will be stable and aligned.

Ensure that all workers involved in the installation are properly trained, equipped with necessary personal protective equipment (PPE), and briefed on safety protocols. Safety should always be a priority during installation to prevent accidents and injuries.

Now that your site is prepared, it’s time to start the installation of your warehouse rack system. Here are the key steps:

Begin by assembling the vertical columns or upright frames. Erect these frames in position, ensuring that they are perfectly plumb and level. Bracing may be necessary depending on the system type, especially for taller racks.

Once the frames are securely in place, insert the horizontal beams at the appropriate height. These beams will support the pallets or goods stored on the racks. If you’re installing shelving, add the necessary decking or wire mesh at this stage. Be sure to secure the beams with locking pins or clips to prevent them from dislodging.

Drill anchor holes through the footplates of the frames, then insert anchors (such as wedge or epoxy anchors) into the holes. This ensures that the racking system is securely fixed to the floor. Follow the manufacturer’s recommendations for anchor placement and use high-quality anchors to guarantee stability.

Add any accessories such as column protectors, back connectors, and row spacers. You may also want to install safety barriers or guardrails around the racking system to prevent accidents in busy warehouse environments.

Proceed bay by bay to install the remaining sections of the racking system. Use the first bay as a reference point, making sure each new bay is aligned properly with the first. Regularly check that the system is level, plumb, and square.

Once the installation is complete, conduct a thorough inspection of the entire system. Check for any loose bolts, uneven beams, or incorrectly installed components. Ensure that all safety features are in place and that load signs are clearly visible. Document the installation process and maintain records for future inspections.

After the racking system is installed, it’s important to establish a routine for inspection and maintenance. This ensures the system’s long-term functionality and safety.

Set up a regular inspection schedule to check the condition of the warehouse rack system. Look for any signs of wear, damage to beams or columns, or loose connections. Inspections should be conducted at least once a year or more frequently if the system is subject to heavy usage.

If any part of the racking system is damaged, it should be repaired or replaced immediately. Damaged racks can pose a significant safety hazard and undermine the integrity of the entire system.

Ensure that load capacity signage is up to date and clearly visible. Keep accurate records of all inspections, repairs, and maintenance activities. This documentation will help ensure that the system continues to operate safely and efficiently.

Ensure all warehouse personnel are trained in the proper use of the racking system. Provide training on load limits, proper handling of goods, and safety procedures to minimize the risk of accidents.

Proper installation of a warehouse rack system is essential for maximizing warehouse space, improving workflow, and ensuring safety. By following the steps outlined in this guide, you can ensure that your racking system is installed correctly, complies with safety standards, and remains functional for years to come. Whether you’re installing pallet racks, selective racking, or shelving systems, thorough planning and attention to detail will help you achieve optimal results.